Stringent Supplier Selection

At Genki Sushi, we source quality ingredients through suppliers stringently selected from all over the world. We have established a quality management system to ensure food safety so that customers can enjoy our food with peace of mind.

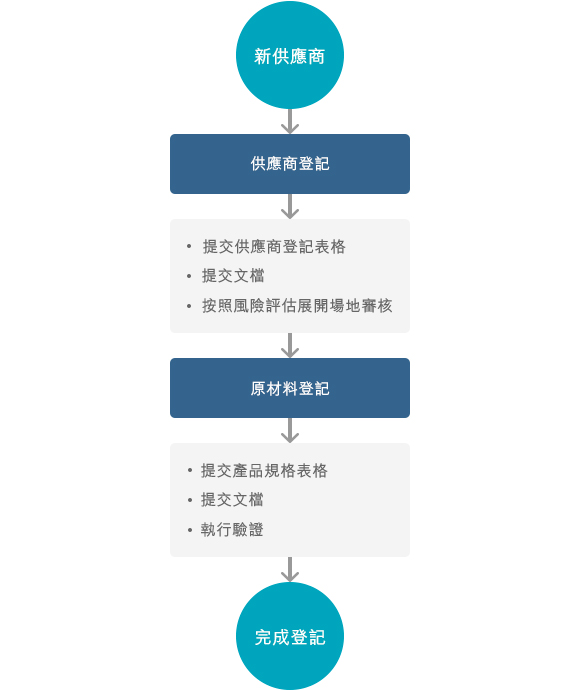

How Our Suppliers Are Selected

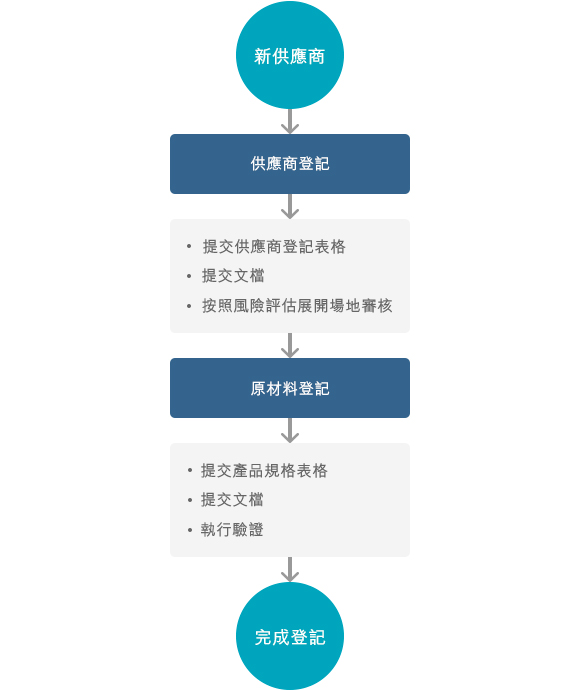

Supplier Registration

Annual Supplier Management and Assessment Program

Meanwhile, we have implemented a comprehensive Annual Supplier Management and Assessment Program for registered suppliers. The program's supply chain and quality assurance assessment helps monitor suppliers to ensure that they meet the relevant standards. Suppliers who fail to meet the set standards will immediately have their contracts terminated.

Quality Assurance Measurement

- Legal Requirement & Food Safety Foundation System

- Factory GMP

- Warehouse & Logistics

- Risk Management System

- In-house Laboratory

- Traceability

Comprehensive Quality Management System

Genki Sushi is committed to offering quality and diversified Japanese dining experience. To achieve this, a comprehensive and systematic Quality Management System has been established to effectively implement preventive control measures, safeguarding food safety during the process of raw material management, manufacturing and cooking, storage and transportation of products, and delivery of products and services to customers.

Risk Assessment and Management

Food safety and quality are reassured through a structured quality management program that assesses the potential risk levels of the related food items with appropriate measures.

Material Qualification and Management

The ingredients procured must comply with the relevant regulatory requirements of the Hong Kong SAR Government. We will also ensure that all Genki Sushi stores, as well as the food and beverage items sold to customers, meet the respective hygiene and food safety standards.

Audit Management for Suppliers and Restaurant Outlets

Both internal and third-party audits are conducted to review and validate the effectiveness in managing food safety and implementing the Quality Management System.

Customer Feedback Management

We place great importance on feedback from customers, and ensure that customer complaints are carefully reviewed before taking relevant action to follow up.

Traceability and Recall Program

We have established a traceable supply chain system to track the sources and origins of our food and ingredients. This system allows us to closely monitor food safety from farm to table and effectively manage and control food quality.

Quality System Review

Regular reviews of food safety policies, standards and procedures are conducted to manage any food safety risks associated with alternations in products, processes, technologies and consumer needs.

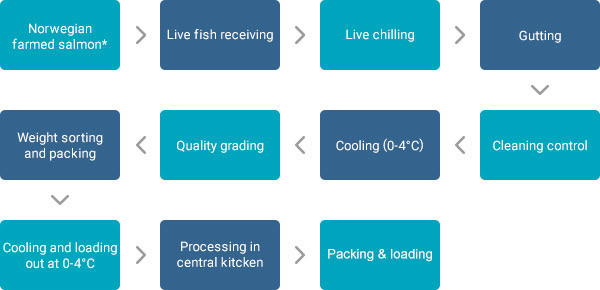

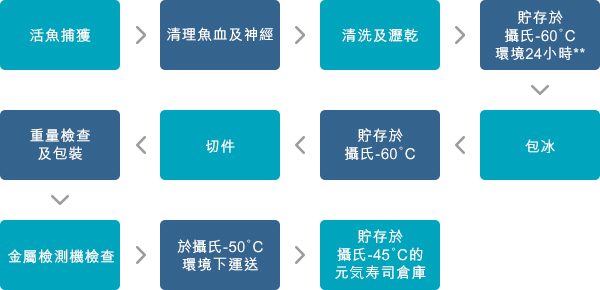

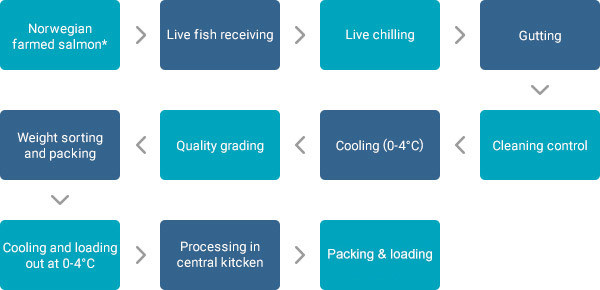

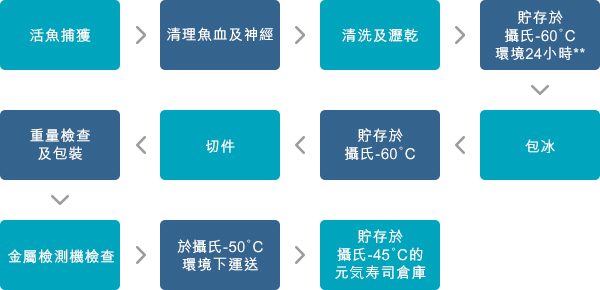

Processing Flow of Ingredients

*Norwegian farmed salmon feed is heat-treated to eliminate parasites. Every batch of salmon comes with a health certificate from the Norwegian food safety department that confirms its source and species.

**The food quality is ensured by adhering to the freezing treatment guidelines in The Code of Practice for Fish and Fishery Products as prescribed by the Codex Alimentarius Commission (CAC) and the Centre of Food Safety (CFS) under Hong Kong Food and Environment Hygiene Department, including storing all ingredients at -20°C or below for seven days; or -35°C or below for about 20 hours for fish intended for raw consumption to kill parasites.

Regular Testing

In the past five years, approximately 1,000 food items were sent to third-party testing institutes' laboratories for annual testing. Approximately 98% of the items passed the tests and met the relevant food safety and quality standards. Going forward, we will continue to place food safety as our top priority and conduct regular tests to ensure that customers can enjoy our food with peace of mind.

Strict Hygiene to Ensure Food Safety

With food safety as our top priority, Genki Sushi adheres to stringent hygiene and cleanliness standards. We ensure that all our staff comply with the following hygiene requirements:

Professional Team to Safeguard Food Safety

With food safety as our top priority, apart from carefully selecting and monitoring our suppliers, Genki Sushi also requires all our staff to adhere to strict hygiene standards. A quality assurance team is in place to ensure that our store environment as well as food and beverage items meet the relevant standards so that we can provide a pleasant and safe dining experience to our customers.

- The Quality Assurance Team is formed by staff members who have completed the professional trainings about food safety and related skills

- All new food and beverage items must go through a risk assessment conducted by the Quality Assurance Team before selling to customers, to ensure that the items comply with the regulation set by the Hong Kong SAR Government as well as the “Food Hygiene Code” by FEHD

- Ingredients and in-store food samples are regularly collected by the Quality Assurance Team and sent to independent third-party testing institute(s) for microbiological tests to ensure the food items fulfil the relevant standards. We have also appointed SGS Hong Kong to conduct store inspections to ensure the food quality control measures are effectively executed.

Stringent Supplier Selection

At Genki Sushi, we source quality ingredients through suppliers stringently selected from all over the world. We have established a quality management system to ensure food safety so that customers can enjoy our food with peace of mind.

How Our Suppliers Are Selected

Supplier Registration

Annual Supplier Management and Assessment Program

Meanwhile, we have implemented a comprehensive Annual Supplier Management and Assessment Program for registered suppliers. The program's supply chain and quality assurance assessment helps monitor suppliers to ensure that they meet the relevant standards. Suppliers who fail to meet the set standards will immediately have their contracts terminated.

Supplier Quality Assurance Criteria

- Legal Requirement & Food Safety Foundation System

- Factory GMP

- Warehouse & Logistics

- Risk Management System

- In-house Laboratory

- Traceability

Comprehensive Quality Management System

Genki Sushi is committed to offering quality and diversified Japanese dining experience. To achieve this, a comprehensive and systematic Quality Management System has been established to effectively implement preventive control measures, safeguarding food safety during the process of raw material management, manufacturing and cooking, storage and transportation of products, and delivery of products and services to customers.

Risk Assessment and Management

Food safety and quality are reassured through a structured quality management program that assesses the potential risk levels of the related food items with appropriate measures.

Material Qualification and Management

The ingredients procured must comply with the relevant regulatory requirements of the Hong Kong SAR Government. We will also ensure that all Genki Sushi stores, as well as the food and beverage items sold to customers, meet the respective hygiene and food safety standards.

Audit Management for Suppliers and Restaurant Outlets

Both internal and third-party audits are conducted to review and validate the effectiveness in managing food safety and implementing the Quality Management System.

Customer Feedback Management

We place great importance on feedback from customers, and ensure that customer complaints are carefully reviewed before taking relevant action to follow up.

Traceability and Recall Program

We have established a traceable supply chain system to track the sources and origins of our food and ingredients. This system allows us to closely monitor food safety from farm to table and effectively manage and control food quality.

Quality System Review

Regular reviews of food safety policies, standards and procedures are conducted to manage any food safety risks associated with alternations in products, processes, technologies and consumer needs.

Processing Flow of Ingredients

*Norwegian farmed salmon feed is heat-treated to eliminate parasites. Every batch of salmon comes with a health certificate from the Norwegian food safety department that confirms its source and species.

**The food quality is ensured by adhering to the freezing treatment guidelines in The Code of Practice for Fish and Fishery Products as prescribed by the Codex Alimentarius Commission (CAC) and the Centre of Food Safety (CFS) under Hong Kong Food and Environment Hygiene Department, including storing all ingredients at -20°C or below for seven days; or -35°C or below for about 20 hours for fish intended for raw consumption to kill parasites.

Regular Testing

In the past five years, approximately 1,000 food items were sent to third-party testing institutes’ laboratories for annual testing. Approximately 98% of the items passed the tests and met the relevant food safety and quality standards. Going forward, we will continue to place food safety as our top priority and conduct regular tests to ensure that customers can enjoy our food with peace of mind.

Strict Hygiene to Ensure Food Safety

With food safety as our top priority, Genki Sushi adheres to stringent hygiene and cleanliness standards. We ensure that all our staff comply with the following hygiene requirements:

Professional Team to Safeguard Food Safety

With food safety as our top priority, apart from carefully selecting and monitoring our suppliers, Genki Sushi also requires all our staff to adhere to strict hygiene standards. A quality assurance team is in place to ensure that our store environment as well as food and beverage items meet the relevant standards so that we can provide a pleasant and safe dining experience to our customers.

- The Quality Assurance Team is formed by staff members who have completed the professional trainings about food safety and related skills

- All new food and beverage items must go through a risk assessment conducted by the Quality Assurance Team before selling to customers, to ensure that the items comply with the regulation set by the Hong Kong SAR Government as well as the “Food Hygiene Code” by FEHD

- Ingredients and in-store food samples are regularly collected by the Quality Assurance Team regularly for and sent to independent third-party testing institute(s) for microbiological tests to ensure the food items fulfil the relevant standards. We have also appointed SGS Hong Kong to conduct store inspections to ensure the food quality control measures are effectively executed.

Stringent Supplier Selection

At Genki Sushi, we source quality ingredients through suppliers stringently selected from all over the world. We have established a quality management system to ensure food safety so that customers can enjoy our food with peace of mind.

How Our Suppliers Are Selected

Supplier Registration

Annual Supplier Management and Assessment Program

Meanwhile, we have implemented a comprehensive Annual Supplier Management and Assessment Program for registered suppliers. The program's supply chain and quality assurance assessment helps monitor suppliers to ensure that they meet the relevant standards. Suppliers who fail to meet the set standards will immediately have their contracts terminated.

Supply Measurement

- Delivery Reliability

- Contract Fulfillment

- Innovation Development Capability

- Service Execellence

Quality Assurance Measurement

- Quality Execellence

- Legal Compliance

- Quality Compliance

- Verification results according to third party

- Site Audit Food Safety and Quality

Comprehensive Quality Management System

Genki Sushi is committed to offering quality and diversified Japanese dining experience. To achieve this, a comprehensive and systematic Quality Management System has been established to effectively implement preventive control measures, safeguarding food safety during the process of raw material management, manufacturing and cooking, storage and transportation of products, and delivery of products and services to customers.

Risk Assessment and Management

Food safety and quality are reassured through a structured quality management program that assesses the potential risk levels of the related food items with appropriate measures.

Material Qualification and Management

The raw materials must be in compliance with the related regulatory requirements by the Hong Kong SAR Government, as well as international food safety standards such as ISO22000, HACCP and GMP. It is ensured that all Genki Sushi stores, food and beverage items being sold to the customers are fulfilling the respective hygiene and food safety standards.

Audit Management for Suppliers and Restaurant Outlets

Both internal and third-party audits are conducted to review and validate the effectiveness in managing food safety and implementing the Quality Management System.

Customer Feedback Management

We place great importance on feedback from customers, and ensure that customer complaints are carefully reviewed before taking relevant action to follow up.

Traceability and Recall Program

We have established a traceable supply chain system to eliminate the possibility of any questionable products being served to customers.

Quality System Review

Regular reviews of food safety policies, standards and procedures are conducted to manage any food safety risks associated with alternations in products, processes, technologies and consumer needs.

Processing Flow of Ingredients

*Norwegian farmed salmon feed is heat-treated to eliminate parasites. Every batch of salmon comes with a health certificate from the Norwegian food safety department that confirms its source and species.

**The food quality is ensured by adhering to the freezing treatment guidelines in The Code of Practice for Fish and Fishery Products as prescribed by the Codex Alimentarius Commission (CAC) and the Centre of Food Safety (CFS) under Hong Kong Food and Environment Hygiene Department, including storing all ingredients at -20°C or below for seven days; or -35°C or below for about 20 hours for fish intended for raw consumption to kill parasites.

Regular Testing

In the past five years, approximately 1,000 food items were sent to third-party laboratories for annual testing. Approximately 98% of the items passed the tests and met the relevant food safety and quality standards. Going forward, we will continue to place food safety as our top priority and conduct regular tests to ensure that customers can enjoy our food with peace of mind.

SGS

Genki Sushi is committed to improving the food quality and safety. In order to provide the high-quality products to consumers, we work closely with SGS Hong Kong and appoint SGS to conduct food testing and various audits in the global supply chain.

SGS is the world's leading inspection, verification, testing and certification company which is recognized as the global benchmark for quality and integrity, with more than 89,000 employees and a network of more than 2,600 offices and laboratories around the world.

Genki Sushi Quality Control Department has established a yearly plan on food testing. From raw materials to finished products, selected ingredient will be sent to SGS Hong Kong for regular test includes but not limited to microbiological test, shelf-life, heavy metals, preservatives as well as parasite test. In addition, SGS Hong Kong has arranged a series of unannounced food sampling in different outlets. In the coming year, SGS Hong Kong will conduct an annual check on approximately 300 food items for Genki Sushi to ensure that the food and beverages' quality can meet the hygiene and food safety standards.

Besides food testing, Genki Sushi appoints SGS Hong Kong to audit selective suppliers. Genki Sushi strives to improve the production line management and the production process is strictly controlled to meet international standards.

More information on SGS, please visit https://www.sgsgroup.com.hk/

Strict Hygiene to Ensure Food Safety

With food safety as our top priority, Genki Sushi adheres to stringent hygiene and cleanliness standards. We ensure that all our staff comply with the following hygiene requirements:

Professional Team to Safeguard Food Safety

With food safety as our top priority, apart from carefully selecting and monitoring our suppliers, Genki Sushi also requires all our staff to adhere to strict hygiene standards. A quality assurance team is in place to ensure that our store environment as well as food and beverage items meet the relevant standards so that we can provide a pleasant and safe dining experience to our customers.

- The Quality Assurance Team is formed by staff members who have completed the professional trainings about food safety and related skills

- All new food and beverage items must go through a risk assessment conducted by the Quality Assurance Team before selling to customers, to ensure that the items comply with the regulation set by the Hong Kong SAR Government as well as the “Food Hygiene Code” by FEHD

- The Quality Assurance Team will conduct regular audits on the “food safety and environmental hygiene” management system and executions at all branches

- Ingredients and in-store food samples are collected by the Quality Assurance Team regularly for microbiological tests to ensure that food items fulfil the relevant standards